If your floors feel chilly in winter or your AC never seems to catch up in summer, your crawl space may be the reason. In Central and South Texas, where humidity swings and long cooling seasons are the norm, insulating the crawl space is a smart way to boost comfort, protect your home from moisture, and reduce energy costs. Here is what to expect on cost, timing, materials, and whether to go DIY or hire a pro, plus clear answers to common questions from Texas homeowners.

Why Your Texas Crawl Space Needs Attention

Crawl spaces sit between your conditioned living area and the warm, humid ground. Without proper insulation and moisture control, that space can become a pathway for heat, cold, odors, and damp air. The results show up as higher utility bills, uneven floor temperatures, musty smells, cupping wood floors, and even mold risks.

Insulation works best when paired with air sealing and moisture management. In our region, that means addressing ground vapor, outside air infiltration, and rim joist leaks so your new insulation can do its job.

What Is the Average Cost to Insulate a Crawl Space?

Costs vary based on size, accessibility, and material choice. Here are typical Texas ranges for a 600 to 1,000 square foot crawl space:

- Fiberglass batts between floor joists: 1.50 to 3.50 dollars per square foot installed, often 1,200 to 3,500 dollars total.

- Rigid foam board on crawl space walls with sealed vents: 3.00 to 6.00 dollars per square foot of wall area.

- Closed cell spray foam at rim joists or full coverage: 4.00 to 7.50 dollars per square foot for targeted areas, more for full encapsulation.

- Encapsulation with ground vapor barrier, sealed seams, wall insulation, and dehumidifier when needed: 3,000 to 10,000 dollars, depending on conditions.

If you are budgeting, remember that moisture work drives cost more than insulation alone. Many homes benefit from a hybrid approach, such as fiberglass or rigid foam with careful air sealing at rim joists.

Geo-Insulation provides detailed, written estimates after a personal inspection and can help you explore any available local rebates.

Is Crawl Space Insulation Worth It?

For most Texas homes, yes. Well executed crawl space insulation and moisture control can deliver:

- Lower energy bills, often 10 to 20 percent savings when combined with air sealing.

- More even floor temperatures for year round comfort.

- Reduced humidity migration into living areas.

- Protection for hardwoods and framing from seasonal moisture swings.

- Quieter floors and fewer drafts.

These gains are most noticeable in homes with vented crawl spaces, older flooring systems, or visible air gaps at the rim joist. Add a properly sealed vapor barrier and you also reduce mold risk and musty odors.

How Long Does Installation Take?

Most projects take 1 to 2 days for straightforward spaces. Add time for these situations:

- Heavy debris removal or old insulation removal: plus a half day to a full day.

- Extensive air sealing of rim joists, ducts, or penetrations: plus a half day.

- Full encapsulation with vapor barrier and wall insulation: 2 to 3 days.

- Dehumidifier installation and electrical work: plus several hours.

Professional crews move faster, especially in tight or hard to access crawl spaces, and handle the cleanup for you.

Materials 101, What to Use in Texas

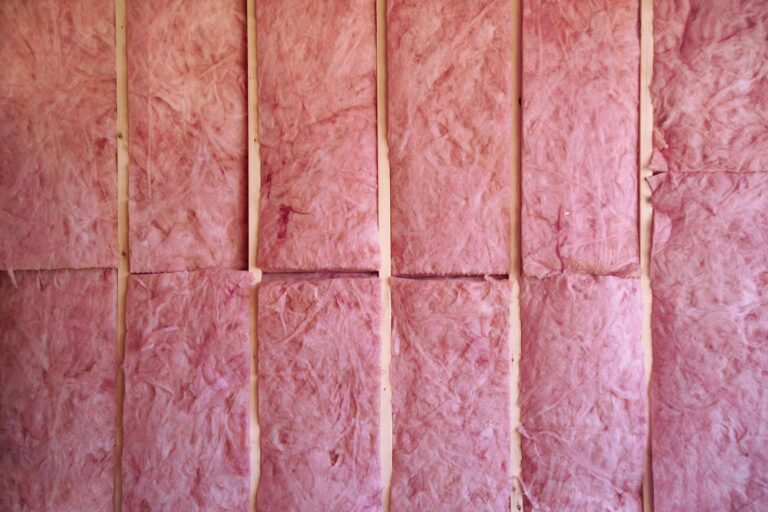

- Fiberglass batts: Common and cost effective for insulating the floor above the crawl space. Works best with proper air sealing and a code correct vapor retarder facing.

- Closed cell spray foam: Excellent air seal and high R value per inch. Ideal for rim joists and hard to reach areas. It also resists moisture and adds rigidity to the assembly.

- Rigid foam board on walls: Useful if converting to an unvented, conditioned crawl space. Combine with a sealed ground vapor barrier and closed vents.

- Ground vapor barrier: A must for moisture control. Use at least 10 to 12 mil poly, sealed at seams and edges.

In San Antonio and nearby areas, many homes do well with fiberglass in joists plus spray foam at the rim joist and a ground vapor barrier. Encapsulation is the gold standard for persistent moisture problems.

Should Paper Go Up or Down for Crawl Space Insulation?

If you use kraft faced fiberglass under the floor, the paper facing is the vapor retarder. It should face the warm in winter side, which means up toward the subfloor in Texas. Do not leave the paper exposed downward. Secure batts so they touch the subfloor, then use mechanical supports like insulation hangers or netting. Avoid double vapor barriers, such as kraft face plus a plastic wrap under the batts, which can trap moisture.

Moisture Protection, The Make or Break Step

- Install a continuous ground vapor barrier. Overlap seams 6 to 12 inches and tape them. Extend the barrier up piers a few inches and seal.

- Air seal rim joists, sill plates, and penetrations with spray foam or caulk. This reduces humid air infiltration and improves insulation performance.

- Decide on venting. In our climate, many homes benefit from converting to an unvented crawl space with wall insulation and sealed vents, especially if humidity is a recurring issue.

- Manage drainage. Ensure downspouts and grading move water away from the foundation. Fix plumbing leaks before insulating.

DIY or Professional Installation?

DIY can work if your crawl space is clean, reasonably dry, and easy to access, and if you are installing simple fiberglass batts with basic air sealing. You will need protective gear, lighting, a staple gun, hangers or netting, tape for vapor barrier seams, and patience.

Consider hiring a pro when:

- You need spray foam at rim joists or full spray foam coverage.

- There is standing water, mold, or heavy moisture.

- The space is tight, complex, or contains extensive wiring or ducts.

- You want full encapsulation with wall insulation and mechanical drying.

Professionals will also spot structural or moisture red flags and size materials correctly. If you prefer a turnkey solution in South Central Texas, speak with a insulation contractors in San Antonio who know our climate and codes.

How Long Does Crawl Space Insulation Last?

- Fiberglass batts: 15 to 25 years when kept dry and properly supported. Moisture, pests, or sagging reduce lifespan.

- Closed cell spray foam: 25 years or more when protected from UV and bulk water.

- Rigid foam: 20 to 30 years in dry conditions.

Annual or biannual checks are smart. Look for sagging, gaps, damp spots, or torn vapor barrier seams, and address small issues early.

Simple DIY Tips to Boost Results

- Seal obvious gaps at the rim joist with a can of foam before installing batts.

- Use insulation supports every 12 to 16 inches to prevent sagging.

- Keep a 3 inch clearance around recessed lights or heat sources unless rated for direct contact.

- Label photos of pipe locations before you cover the area in insulation to make future repairs easier.

- Wear a respirator, gloves, and eye protection, and place a drop cloth at the crawl entrance to keep your home clean.

Summary, A Warmer Floor and Lower Bills Start Below

Insulating your crawl space pays off in comfort, energy savings, and long term home protection. Expect most projects to cost from the low thousands to the mid range depending on size, moisture needs, and material choices. In Texas, pair insulation with a solid vapor barrier and air sealing, and face kraft paper up toward the subfloor. DIY is possible for simple batts, but professional help is best for spray foam, encapsulation, and moisture issues.

If you are ready to improve comfort and lower bills, talk to a trusted San Antonio insulation company, like Geo Insulation, for a tailored plan that fits your home.